News

The future of packaging will be increasingly Green

While the European Commission aims at the goal of total recycling of plastic packaging by 2030, let's see together what is the situation in the industry today.

The European Commission has decided to make Europe the leader in the fight against plastic, aiming, by 2030, at the total recycling of all plastic packaging.

A strategy that - as the vice president of the Commission Frans Timmermans made clear - does not aim to hit the plastics industry, considered indispensable for the European economy given that it employs 1.5 million people in the Union, but wants to offer a concrete answer to the pollution emergency and the invasion of microplastics in the environment and in the food chain.

According to WWF data, in fact, every year at least 8 million tons of plastic end up in the world's oceans and, to date, it is estimated that there are more than 150 million. It is also well known what the decomposition times of this material (90 years on average) are and the social cost that involves the pollution of seas and rivers.

To this, then, we must add the problem of the depletion of the resources used in production: in fact, plastic is a derivative of petroleum and to produce, for example, 1 kg of PET as much as 2 kg of crude oil and 17.5 liters of water are consumed.

The plastics industry situation today

Even before the introduction of this European law, and well aware of the need to reduce environmental impact and production costs, governments and plastic packaging manufacturers have decided to tackle the problem by adopting different solutions.

On the one hand by opting for Lightweight Engineering, or by reducing the weight (by 25-30%) of the containers and consequently the amount of plastic used and, on the other, by providing the usage of a percentage of recycled plastic (R-PET) in the production of a new container.

In some cases (eg. Germany), far-sighted political choices have been able to generate a real enhancement of waste: through a bail collection system (25/30 euro cents per bottle) the population has an incentive to collect and deliver the bottles, thus reducing the quantity of abandoned waste and speeding up the collection and reuse operations.

Another way, chosen by some producers, is the substitution of PE and PET with materials of vegetal origin (PLA) deriving from the composting of corn starch or from the fermentation of sugar cane. These are 99% biodegradable materials that guarantee decomposition times of only 90-120 days.

United Europe but not the same

Given that the use of recycled PET in no way affects the functionality and technical characteristics of the packaging while, only imperceptibly, on its aesthetic appearance (transparency reduction), it is necessary to highlight how the percentage of R-PET, admitted by law, is different from country to country.

While in Germany the maximum allowed percentage of recycled PET is 80%, in our country it barely reaches 30%. What does this mean? That in Germany the petroleum and water necessary for the production of a bottle are limited to only 20%, while in Italy it reaches 70%.

We are facing a very varied and complex legislative landscape due, for the most part, to political and organizational reasons which, hopefully, the recent European resolution will finally be able to harmonize.

Is a world without plastic possible?

Is now a fact that plastic is essential for many production sectors, also because today there are no alternatives capable of replacing the plastic by 100%: glass, PLA or the recent PHA, cannot be used in all areas and not offer the same characteristics as PET and PE do.

For example, PLA requires very specific management by the consumer, especially in the matter of separate collection. To be able to dispose of a PLA bottle in organic waste, for example, first you need to remove the label, then remove the glue residue and finally separate the cap (which is in PE). Furthermore, this material is easily deformed already at 55 ° C and offers low CO2 retention, thus limiting its use in the bottling of carbonated waters and beverages.

Which is the plastic’s future?

The only possible solution to the state of things, therefore, is that already undertaken by many countries and to which the EU is focusing: the study of technological solutions that allow a further weight reduction of the containers (and therefore of the quantity of plastic) and the increase in the percentage of recycled PET used.

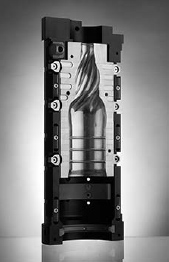

We, the DEMO team, have been working on these alternatives for long time now, offering complete and advanced solutions for the production of low environmental impact PET packaging, offering a 360 ° project management service: from the bottle shape proposal to the container design, from the evaluation of the impact on the production lines when converting the neck, from the construction of the blow mould to the installation and start-up of production.

Would you like more information? Contact us.